Why choose our FRP pipes and systems?

The truth has been unearthed.

Underground infrastructures across North America are old, deteriorated, corroded or simply undersized due to aggressive conditions or environmental changes. There are many cities and industries who are struggling to maintain their underground assets at an in-service condition.

Fiberglass reinforced polymer (FRP) pipes are the sustainable alternatives for any kind of pipeline. Some even state that the FRP pipe is among the greener pipes because of the low manufacturing footprint and the design life expectancy of 100 years. Using FRP pipes and systems will reduce the cost of replacement and rehabilitation as well as the cost of maintenance for the entire life cycle of your infrastructure.

Novinfra and partners are dedicated to manufacture and supply the highest quality FRP pipes with the highest level of service before and after sale. We offer a large range of FRP products for underground, above ground and trenchless applications. Our Circular and non-circular pipes can be designed for pressure or gravity flow condition.

Composition of glassfiber reinforced polyester

Ideal for difficult installations, their high strength, corrosion resistance, and ease of installation position GRP piping systems as the pipe of the future.

Polyester Thermosetting Resin

Silica Sand

Field of use

Sanitary and stormwater pipes

Potable and clean water transmission line and watermain

Liner for pipelines and manhole rehabilitation

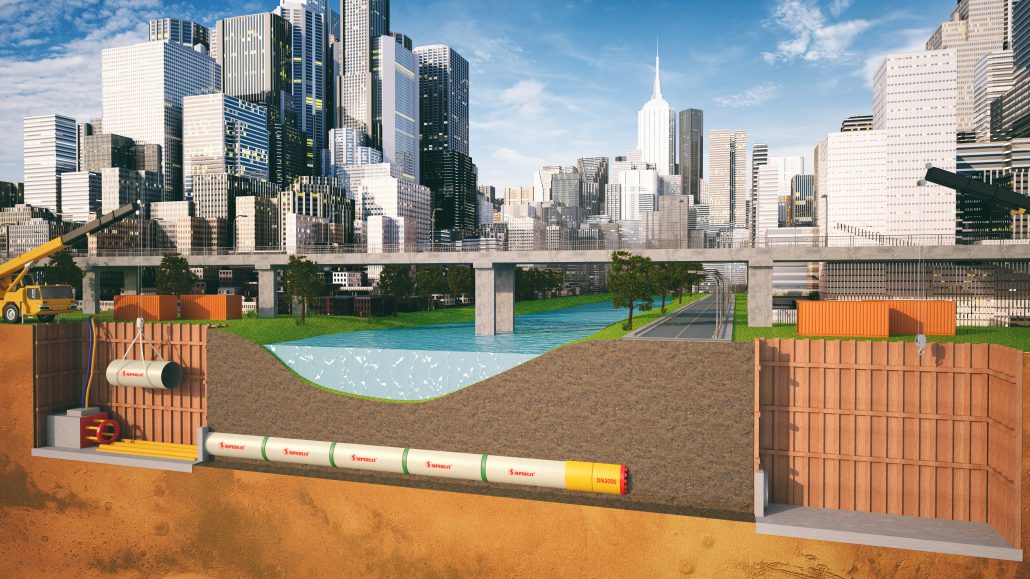

Microtunneling (trenchless)

Drainage and irrigation conveyance lines

Subsea piping, water intake, discharge and outfall lines

Industrial wastewater and chemical lines

Water storage systems

Tanks and galleries

Simply put, the best pipe ever created

The benefits of our FRP pipes and systems

Sustainable

Simpler Installation

Hydraulic Properties

Safe Connections

Engineering Material

FRP Pipes

Superlit uses 3 different manufacturing methods for FRP pipes; Continuous Filament Winding, Centrifugal Casting Technologies, and helical filament winding. Nominal diameter range from 100mm to 4000mm and working pressure class from 14psi to 664psi (up to 580psi). Biaxial FWC FRP pressure pipes are designed to absorb 40% of the surge pressure, without increasing the pressure class.

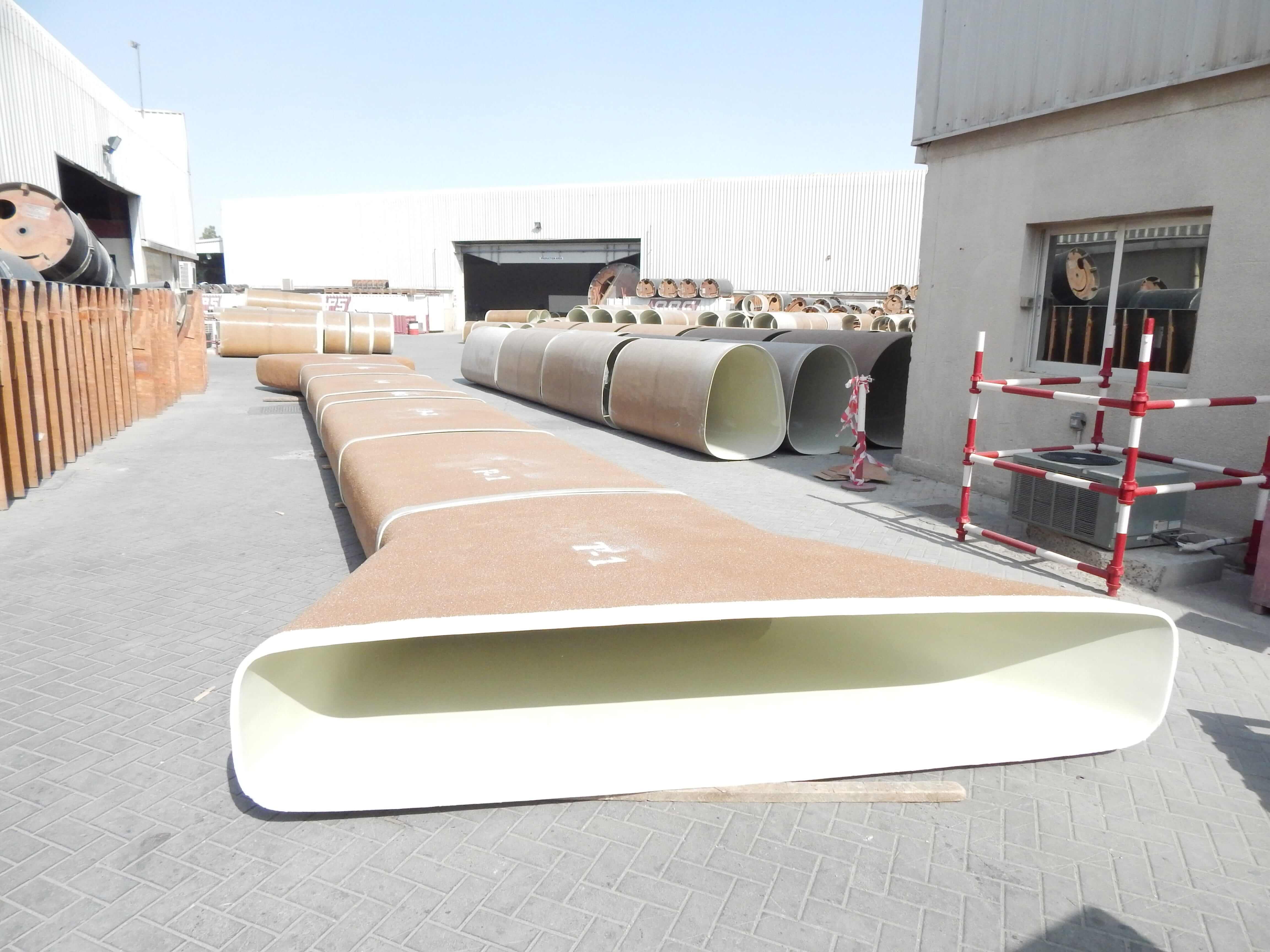

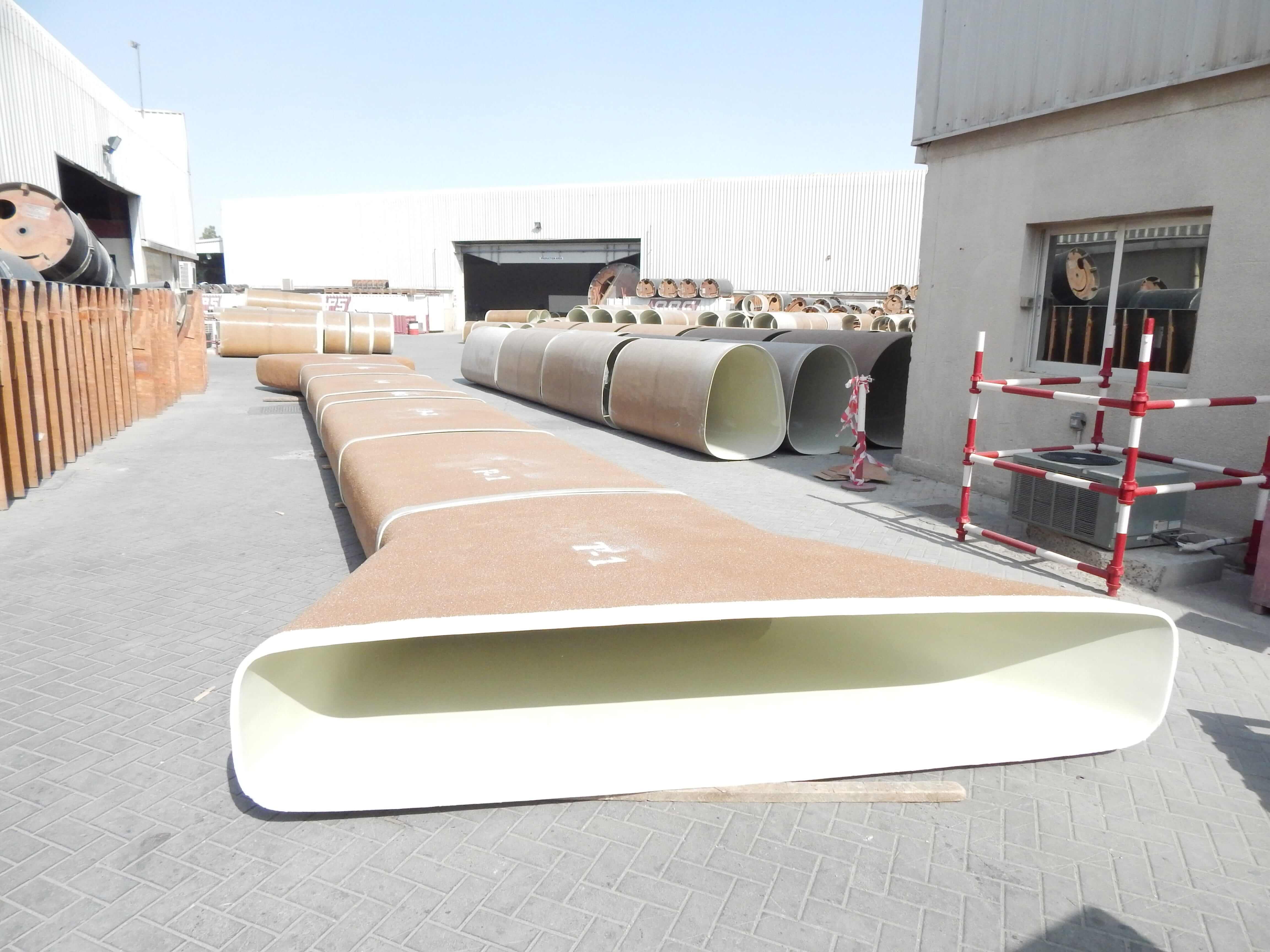

Non-Circular FRP Pipes & Trenchless Rehabilitation Systems

Channeline non-circular pipes are manufactured with hand lay-up and spray lay-up method. These pipes are suitable for both trenchless fully structural rehabilitation and open-trench application for gravity pipelines. The exclusive multi-segmental technology is perfectly designed for relining large diameter and odd shape sewer and storm water pipes.

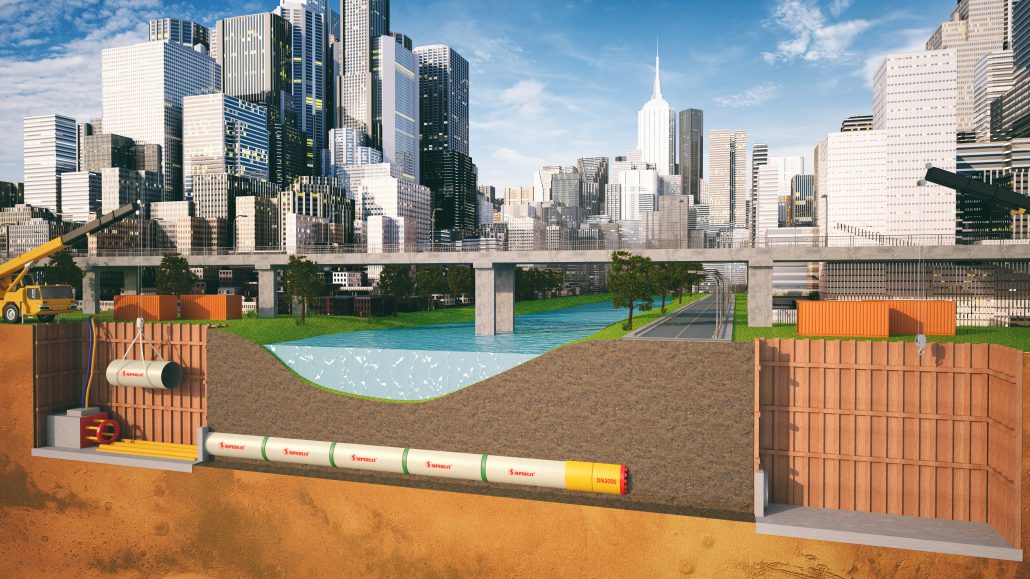

FRP Jacking Pipe (Trenchless)

FRP Jacking pipes are designed to be installed inside a tunnel made by microtunneling technique with a tunnel boring machine (TBM). All the FRP mechanical properties are gathered to design a high axial strength pipe with a wide range of diameters (up to 3000 mm).

FRP Maintenance Holes

Imagine all the advantages of FRP material put in use to manufacture a sustainable manhole. The 4 most common manholes are: Standard, Tangential, Tangential on Bend and Centric Tee.

FRP Retention Systems, Tanks and Galleries

With FRP tanks and retention system, we are able to cater for water storage needs. Recently added to our product range, we now manufacture tanks for oil storage needs.

FRP Fittings and Couplings

Each pipe is delivered mounted on a full-face coupling with fully integrated EPDM gaskets allowing 0,5° to 3° according to different diameters. Also available in slip-on version for repair intervention or tie-in utilization. For pressure pipe applications, we can supply a full-corrosion proof restraint FRP coupling. A wide range of fittings are available with our FRP pipe and systems; Tees, Bends, Reducers, Flages, other connections type.