Joint systems are fully leak-proof and allow application of curves at low angles without use of fittings in long distance pipelines

- Home

- Applications

- Wastewater & Stormwater

Wastewater & Stormwater

Why choose Novinfra?

Keep things flowing with better sewage management.

When it comes to wastewater and stormwater, you need a solution that's going to last. That's why our products benefit from maximum corrosion resistance, longevity, and cost-effective solutions. Plus, they have an estimated service life of 100+ years, and they require minimal to no maintenance.

The deterioration of our sewer systems is no secret. This is an opportunity to modernize and improve our wastewater systems with new options that are more resistant to corrosion, environmental conditions, and prevent the presence of leaks.

Do you have important water projects in the pipeline? With the help of Novinfra’s range of technologies, we can start improving your systems today.

Find options suited to your needs.

Our technology

Our water systems are designed with your needs in mind. Our polymer concrete vertical structures and Fiberglass Reinforced Plastic (FRP) pipes are flexible enough to handle a variety of applications. Whether you're looking for custom structure possibilities or standard applications, for replacement or rehabilitation — we've got you covered.

Armorock’s technologies are made of corrosion-resistant high-strength polymer concrete and are made to last in aggressive environments such as wastewater systems. From standard maintenance holes to lift stations, our vertical structures can also be customized to your exact specifications.

Circular and non-circular FRP pipes and fittings are the best pipeline option for wastewater and stormwater systems as they are lightweight, durable, and corrosion resistant for large-scale projects. Their distinctive joint systems also make them a premium option to prevent leaks, and provide an easier and smoother installation.

No matter the installation method — direct bury, aboveground, microtunnelling, sliplining, etc — our non pressure FRP pipes and PPC vertical structures for sewage are the most cost-effective infrastructures in various applications:

- Trunk sewer line

- Stormwater line and outfall

- Wastewater or stormwater storage unit

- Bridge drainage

The benefits

Smooth interior surface of pipes and robot-made maintenance holes increase flow capacity and self-cleaning capacity

FRP fittings compatible with other materials: T pieces, elbows, flanges, reducers

Corrosion resistant with material warranty

Lightweight

Easy installation

Polymer Concrete Maintenance Hole

Our polymer concrete maintenance holes range from 36" to 192" and we can provide precast maintenance hole bases. Available in circular and non-circular designs.

FRP Pipes

Superlit uses 3 different manufacturing methods for FRP pipes; Continuous Filament Winding, Centrifugal Casting Technologies, and helical filament winding. Nominal diameter range from 100mm to 4000mm and working pressure class from 14psi to 664psi (up to 580psi). Biaxial FWC FRP pressure pipes are designed to absorb 40% of the surge pressure, without increasing the pressure class.

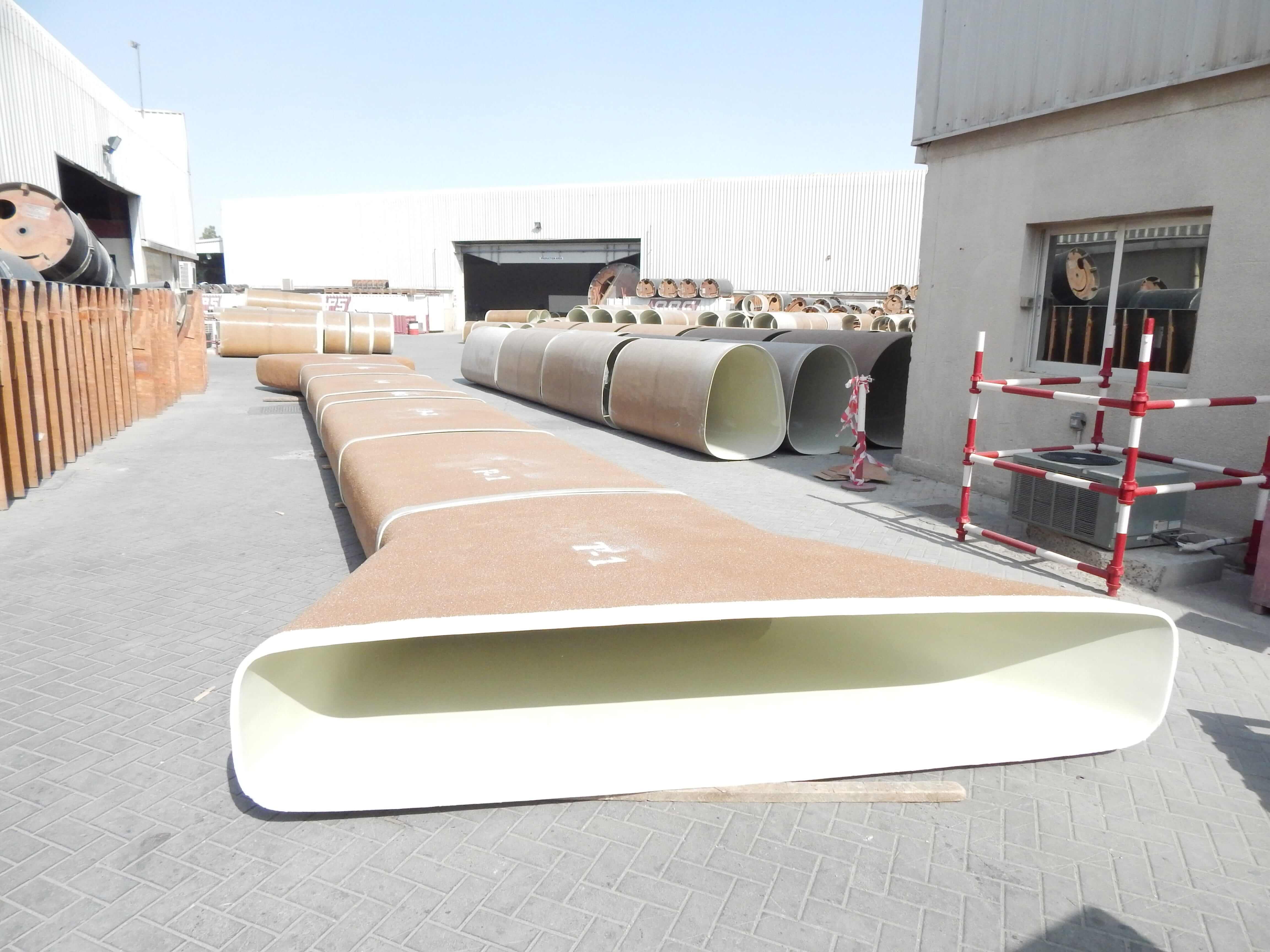

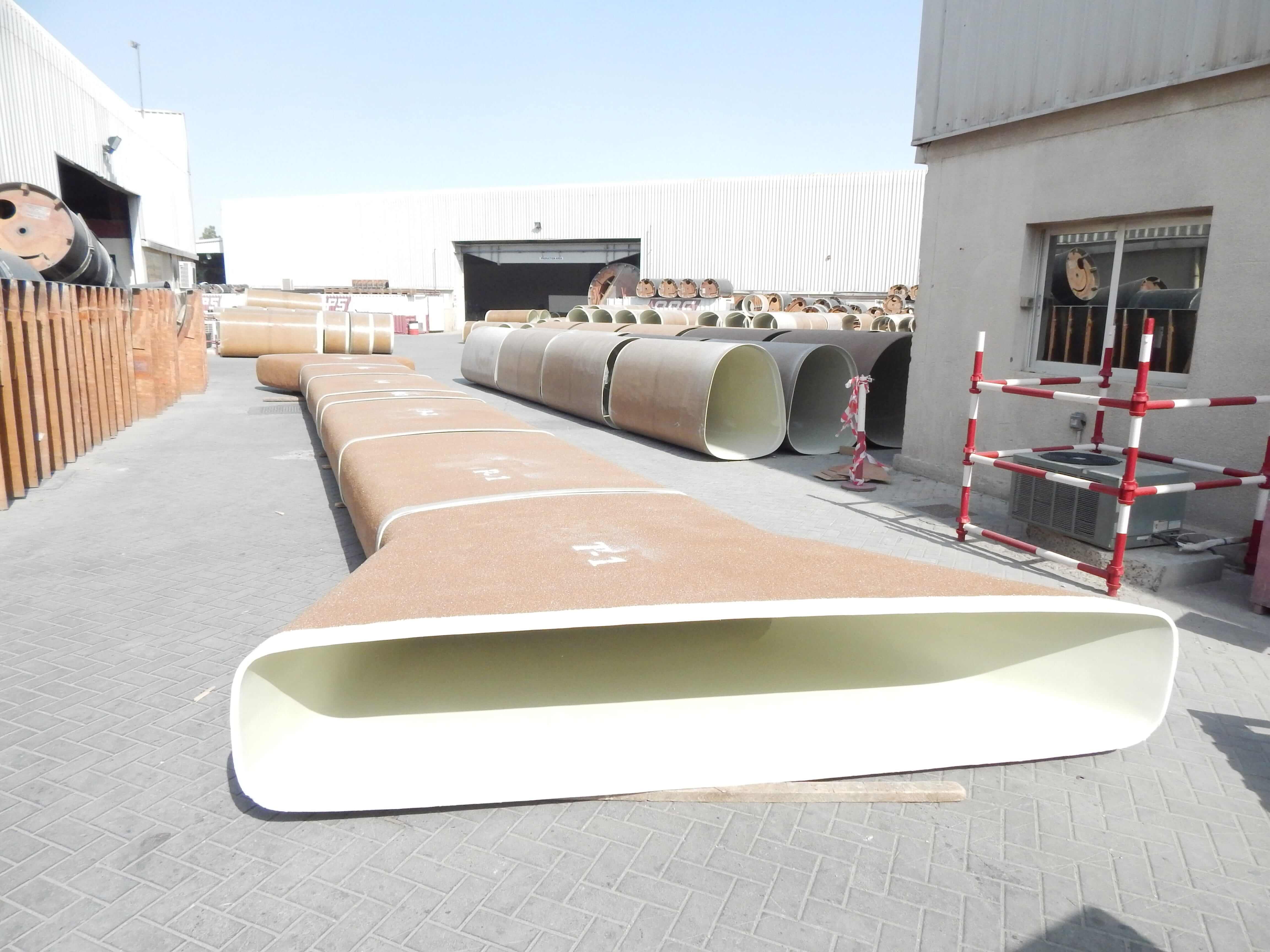

Non-Circular FRP Pipes & Trenchless Rehabilitation Systems

Channeline non-circular pipes are manufactured with hand lay-up and spray lay-up method. These pipes are suitable for both trenchless fully structural rehabilitation and open-trench application for gravity pipelines. The exclusive multi-segmental technology is perfectly designed for relining large diameter and odd shape sewer and storm water pipes.

Rehabilitation Inserts

This solution allows you to rebuild a "new" structure from inside your existing system.

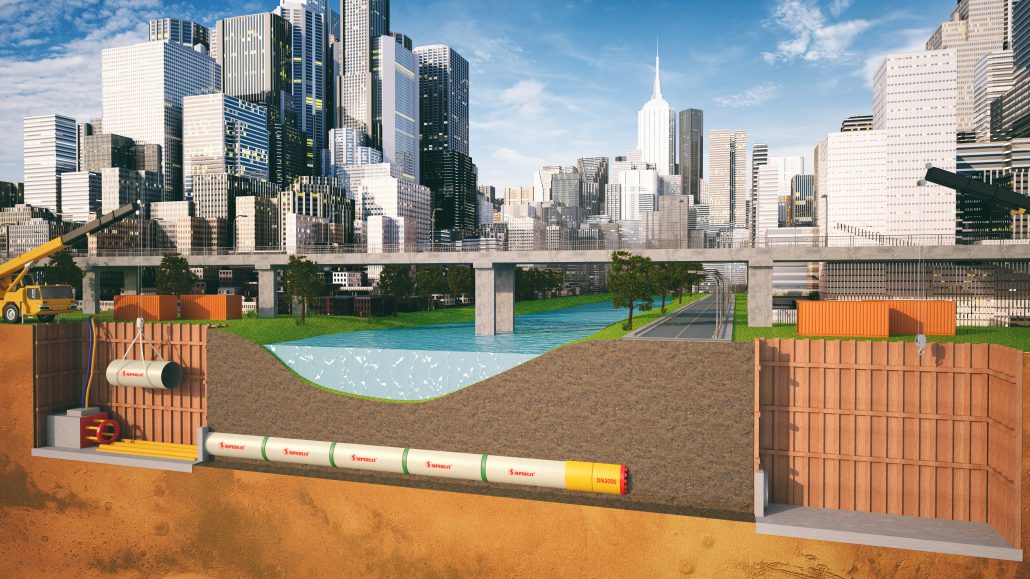

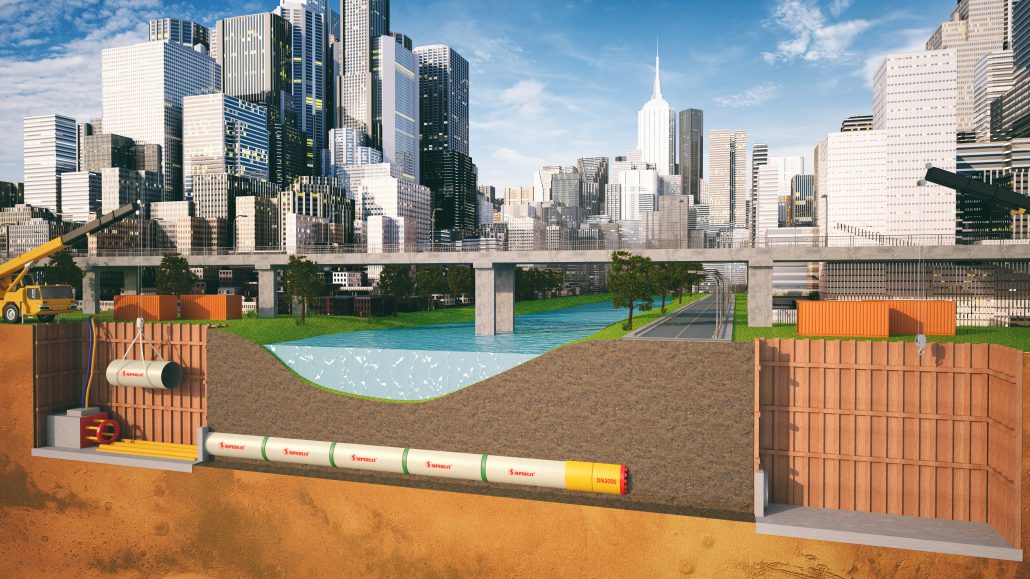

FRP Jacking Pipe (Trenchless)

FRP Jacking pipes are designed to be installed inside a tunnel made by microtunneling technique with a tunnel boring machine (TBM). All the FRP mechanical properties are gathered to design a high axial strength pipe with a wide range of diameters (up to 3000 mm).

FRP Maintenance Holes

Imagine all the advantages of FRP material put in use to manufacture a sustainable manhole. The 4 most common manholes are: Standard, Tangential, Tangential on Bend and Centric Tee.

Lift Stations

Polymer concrete resolves the challenge of H2S exposure to lift stations.

Custom Structures

Base rule: whatever you can produce in traditional concrete, you can do in polymer concrete.