Why choose polymer concrete?

Proven technology – our precast polymer concrete structures have been designed to offer a 50-year corrosion warranty.

The problem of corrosion in wastewater systems is no secret. The industry has tried to address this problem with multiple options in the past years such as coating applications, cast in liners or admixtures. The polymer concrete solutions is different as it doesn’t imply to fix a deficient structure that is reactive to the corrosive environment, but to eliminate the problem at source by installing a material that won't need fixing later on.

By approaching the problem at source with a sustainable approach, the risk of failure and the maintenance level is significantly decreased, even disappeared. For those reasons, polymer concrete structure are one of the most cost-efficient and sustainable solutions in corrosive environment.

Polymer concrete raises the bar of standard performance in wastewater infrastructures. Using polymer concrete means a complete and sustainable upgrade of your systems.

Polymer concrete was introduced in 1950 and became common mostly in Europe by the end of the 1970s. It is a type of concrete in which polymers are used as a binding material instead of cement. Solutions for standard maintenance holes, pump stations, wetwells, siphons, junction boxes and custom structures.

Composition of precast polymer concrete

Polymer concrete is a material made from non-reactive sand, aggregate and resin.

Aggregate

Sand

Fiberglass Rebar

Best practice material

Traditional Concrete vs. Polymer Concrete

Traditional Concrete

Contains cement and potentially reactive aggregates

Polymer Concrete

Completely inert structure - fully corrosion proof straight out of the factory

Porous composition

Non-porous

Compressive strength of 4,000 psi

Flexural strength of 400 psi

Compressive strength of 16,000 psi

Flexural strength of 2,200 psi

Complex installation due to heaviness and thicker walls

Easy installation with the possibility of modular construction

Requires more maintenance and is less durable

Affordable by taking advantage of material properties

Premature deterioration due to freeze-thaw damage

Durable and resilient in conditions of rapid freeze-thaw cycles

No manufacturer warranty available

50-year warranty on the entire structure

The characteristics of a hero

The benefits of polymer concrete

Corrosion Proof

Material Strength

Sustainability

Easy Installation

PPC Maintenance Hole

Our polymer concrete maintenance holes range from 36" to 192" and we can provide precast maintenance hole bases. Available in circular and non-circular designs.

Rehabilitation Inserts

This solution allows you to rebuild a "new" structure from inside your existing system.

Lift Stations

Polymer concrete resolves the challenge of H2S exposure to lift stations.

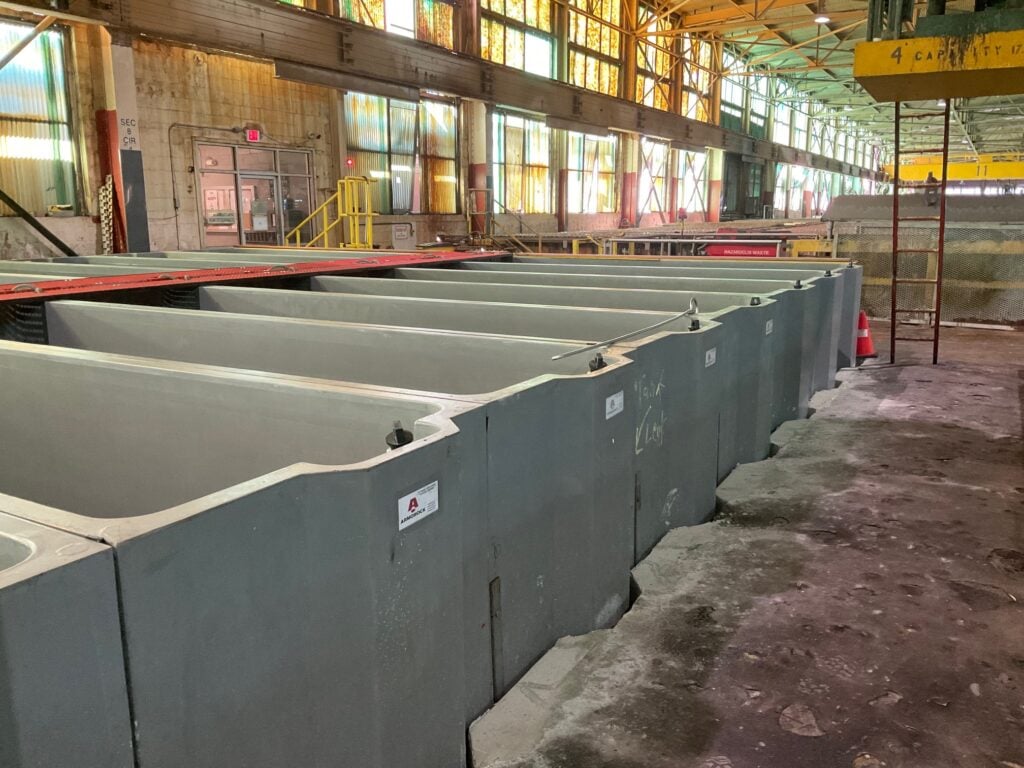

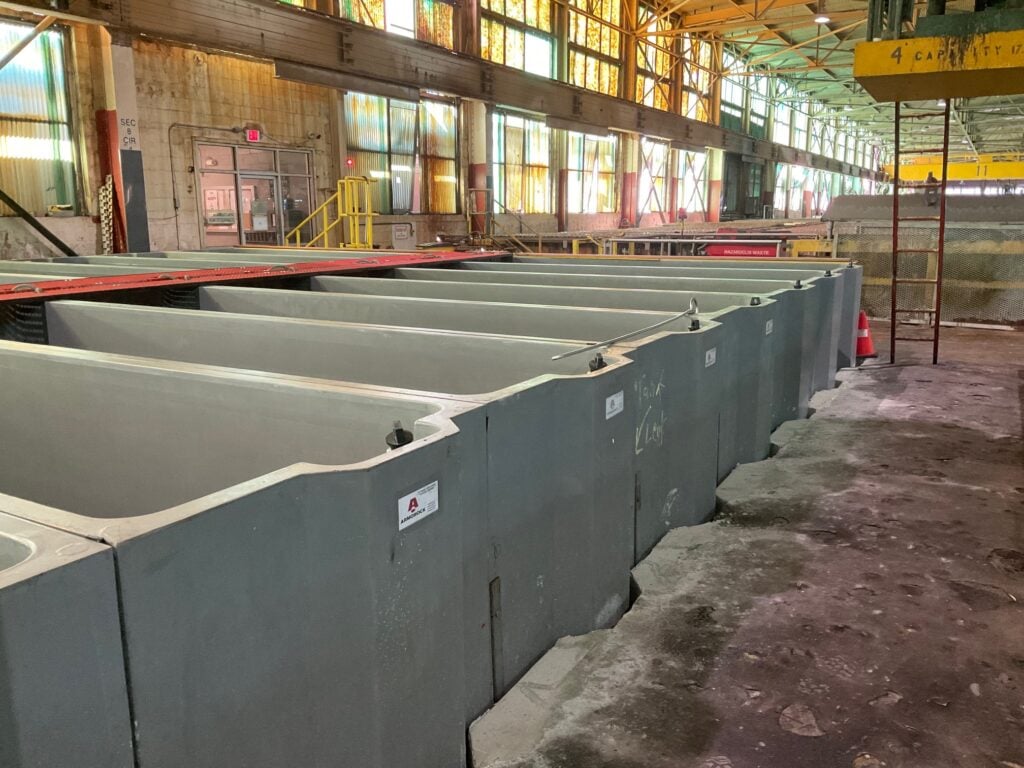

Tanks / Cells

The properties of polymer concrete make it an ideal material for building structures that are exposed to acidic solutions in the mining process.

Custom Structures

Base rule: whatever you can produce in traditional concrete, you can do in polymer concrete.